Laboratories

UNICOIL has two laboratories: one for testing galvanized steel products and another for pre-painted galvanized steel products. Both laboratories have state-of-the-art facilities sourced from renowned agencies from USA and UK to carry out the testing and evaluation of galvanized and pre-painted steel products.

The quality management system at UNICOIL ensures periodical maintenance and calibration of equipment to ensure the accuracy and reliability of testing. The UNICOIL laboratory participates in periodic “Proficiency Test Programs” of ASTM International, a program in which more than 100 laboratories worldwide participate in testing unknown samples to ensure accuracy and reliability of testing at an international level. UNICOIL Laboratories are accredited with ISO17025-2017, from Emirates International Accreditation Center. UNICOIL is the first company that received such accreditation in the flat steel industry within Middle East.

ISO 17025 is the single most important standard for calibration and testing laboratories around the world. Laboratories that are accredited to this international standard have demonstrated that they are technically competent and able to produce precise and accurate test and/or calibration data, providing confidence to customers that the test results provided are reliable and dependable.

Emirates International Accreditation Centre (EIAC) was established pursuant to Law number (27) for the year 2015, issued by His Highness Sheikh Mohammed bin Rashid Al Maktoum, the Vice President and Prime Minister of the UAE, Ruler of Dubai, to become the governmental accreditation body of the Emirate of Dubai.

UNICOIL has in-house, state-of-the-art quality assurance laboratory equipment to perform the tests described below:

Visual Color Test

Standard: ASTM D4086

This is a very important color assessment test. Standard samples and the test sample are positioned side by side and analyzed for shade variations. Some of the colors are metameric, and are considered suitable only after being analyzed using this machine.

Device used : Color cabinet assessment.

Surface Gloss Test

Standard: ASTM D523

Surface gloss relates to the light reflectance from a painted surface. This is a paint property that can be varied by the addition of matting agents or dulling agents during paint manufacture. The gloss levels include low gloss, medium gloss, and high gloss.

Device used : Glosso meter.

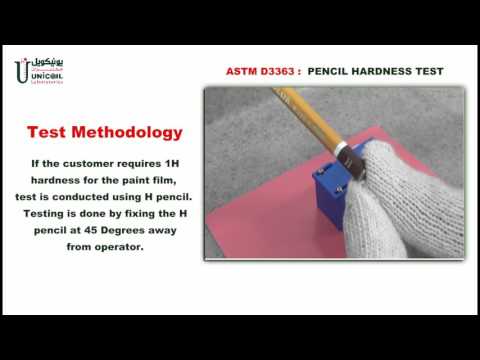

Pencil Hardness Test

Standard: ASTM D3363

The pencil hardness test is used to measure the hardness of the paint film. The results of this test indicates the degree of curing of the paint film. A noncured paint film has a lower pencil hardness, which makes it more likely to be damaged.

Device used: Pencil leads

Solvent Resistance Double-Rub Test

Standard: ASTM D5402/ASTM D7835

The solvent resistance test indicates the stability of a paint film exposed to organic solvents. A greater solvent resistance indicates that the paint film is more stable and durable for outdoor exposure. This test is performed using the organic solvent methyl ethyl ketone.

Device used: Solvent Resistance machine

Reverse Impact Test

Standard: ASTM D 2794

The reverse impact test is a destructive test. This test involves dropping a mass of about 2 kg from a height of about 70 cm, thereby exerting a falling force of 13 Joules. The force will vary according to the thickness of the sheet.The associated energy transfer will result in loosening of the paint film. The stability of the coating is measured by applying tape on the reverse direction of the impact area.

Device used: Impact Tester.

Elasticity Test

Standard : ASTM D522

Elasticity refers to the flexibility of the paint film when the metal sheet is subjected to radius bending. The paint film should not crack while bending the metal. The elasticity is measured with the aid of an eye piece after magnifying an image of the paint surface.

Machine used : Conical mandrel tester.

Information provided in these videos are for demo purpose only to provide an idea of how the tests are performed on Galvanized Steel Coils & Sheets and on Pre-painted Steel Coils & Sheets. Interested persons wanting to know more details about these tests can contact UNICOIL laboratories at lab.test@unicoil.com.sa

FREE Galvanized Steel and Prepainted Galvanized Steel Sheet Testing

UNICOIL offers free laboratory testing services, since the constituent components of galvanized and prepainted steel sheets cannot be identified by the naked eye. The actual components measured in most imported steel sheets do not match the declared components.

The following parameters are tested free of charge in our laboratories:

| Galvanized Steel Parameters | Units |

|---|---|

| Total coated thickness—metal | mm |

| Zinc coating mass | gsm |

| Lead level in zinc | ppm or mg/kg |

| Prepainted Galvanized Steel Parameter | Units |

|---|---|

| Total coated thickness—painted | mm |

| DFT (top and bottom) | microns |

| Zinc coating mass | gsm |

| Lead level in paint (top and bottom) | ppm or mg/kg |

To send your request for a free laboratory test for galvanized steel and prepainted galvanized steel sheets, please contact your sales account manager or customer services, or send your inquiry using the button below:

Send Us Your Inquiry