Main Production Lines

UNICOIL

Main Production Lines

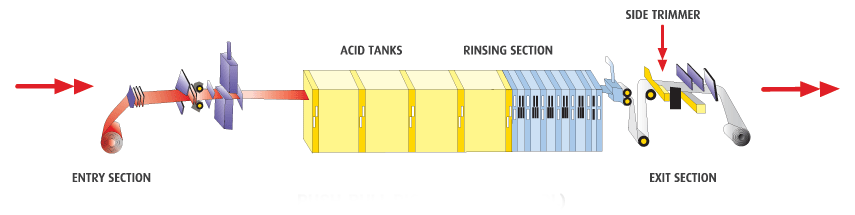

Push-Pull Pickling Line (PPPL)

The turbo-pickling technology cleans the hot-rolled steel strip with hydrochloric acid and ensures the removal of scale prior to rolling the material. The strip edges are trimmed and prepared by an online side trimmer in accordance with the specific width requirements of the customer in the pickling line. The spent acid is regenerated in the acid regeneration plant and then reused, making the whole process environmental friendly.

The turbo-pickling technology cleans the hot-rolled steel strip with hydrochloric acid and ensures the removal of scale prior to rolling the material. The strip edges are trimmed and prepared by an online side trimmer in accordance with the specific width requirements of the customer in the pickling line. The spent acid is regenerated in the acid regeneration plant and then reused, making the whole process environmental friendly.

Bi Product

| Ferric Oxide | > 99% |

| Chloride | 0.5-2.0% |

| Moisture | 0.5% |

| Other elements | Trace |

Iron Oxide

(Indicative Specification)

Iron oxide (Fe2O3) is the obtained by the reaction of oxygen (O2) with iron (Fe). This is a byproduct from the acid regeneration plant, where in the spent acid from the pickling line is processed to recover and reuse the acid. Iron oxide is used in the soft-magnet, paint, and cement manufacturing industries. The typical specifications of this product are as follows: This composition may vary depending on the processing conditions.

Hot Rolled Pickled Trimming Scrap

Edge trimming of the hot-rolled steel coils is essential to eliminate the negative effect of microcracks that develop during the hot-rolling process on the cold-rolling operation. This activity is performed in pickling line, and usually involves trimming about 10 mm to 15 mm wide on each side of the strip, with the trimmed scrap chopped into smaller pieces for discharging into a scrap bucket. Hot-rolled pickled trimming scrap is used for remelting, either by primary or secondary steel manufacturers.

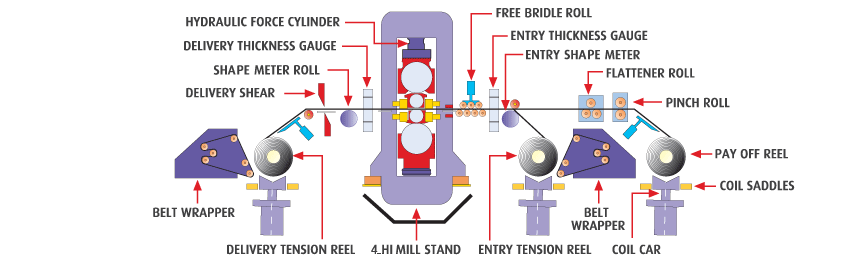

Cold Rolling Mill (CRM) – Full Hard

The cold-rolled reversing mill reduces the pickled and trimmed hot-rolled coils to a specified thickness, ranging from 2 mm right down to 0.25 mm. The work roll-shifting mechanism coupled with a selective roll coolant system guided through an auto shape meter ensures that the produce strip is perfectly flat. The auto gauge control system yields close thickness tolerances that match the international standards.

The cold-rolled reversing mill reduces the pickled and trimmed hot-rolled coils to a specified thickness, ranging from 2 mm right down to 0.25 mm. The work roll-shifting mechanism coupled with a selective roll coolant system guided through an auto shape meter ensures that the produce strip is perfectly flat. The auto gauge control system yields close thickness tolerances that match the international standards.

Bi Product

Full Hard Cold-Rolled Pup Coils

Full Hard Cold-Rolled Pup Coils

Cold-rolled pup coils are generated at the cold-rolling mill. In a single-stand cold-rolling mill, a portion of the coil is wound onto the entry and exit mandrels for gripping during cold rolling, and these portions are cut at the end of the rolling process. Such cold-rolled pup coils will have some unrolled portion of hot-rolled pickled coil and some length of cold-rolled portion that is the incorrect gauge. Cold-rolled pup coils are usually used for remelting, either by primary or secondary steel manufacturers.

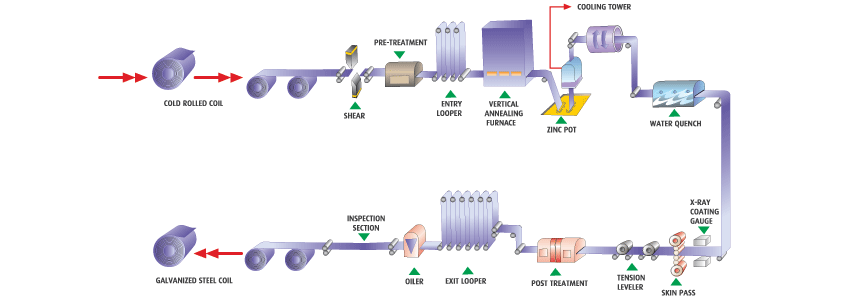

Continuous Galvanizing Line (CGL)

The vertical nonox furnace technology in the galvanizing line uses natural gas to thermally clean the cold-rolled strip by creating a non-oxidizing atmosphere that volatilizes surface hydrocarbons on the strip. In the annealing section of the furnace a mixture of nitrogen and hydrogen gases protects the strip from oxidation as well as preparing the strip for zinc coating. Performing alkali cleaning before the furnace also assists in obtaining excellent zinc adherence.

An online X-ray coating weight gauge controls the accuracy and uniformity of the coating across the width and along the length of the strip, while the skin-pass mill and tension leveler ensure that the strip is flat prior to recoiling.

The vertical nonox furnace technology in the galvanizing line uses natural gas to thermally clean the cold-rolled strip by creating a non-oxidizing atmosphere that volatilizes surface hydrocarbons on the strip. In the annealing section of the furnace a mixture of nitrogen and hydrogen gases protects the strip from oxidation as well as preparing the strip for zinc coating. Performing alkali cleaning before the furnace also assists in obtaining excellent zinc adherence.

An online X-ray coating weight gauge controls the accuracy and uniformity of the coating across the width and along the length of the strip, while the skin-pass mill and tension leveler ensure that the strip is flat prior to recoiling.

Bi Product

Zinc Top Dross

| Min (%) | Max (%) | |

| Zinc | 98 | 99 |

| Aluminum | 1.0 | 1.5 |

| Iron | 0.05 | 0.20 |

| Element | Trace | |

Zinc Top Dross

(Approximate Range)

Zinc dross is generated by the combination of zinc oxide with other impurities such as aluminum, iron, and other alloying elements in the zinc bath that is used for the continuous hot-dip galvanizing line floating on the top of the zinc bath. This dross is collected using dross spoons and put into small dross boxes. Zinc dross is used for recycling of zinc, the production of high-purity zinc oxide, and other applications requiring zinc. The composition may vary depending on the processing conditions.

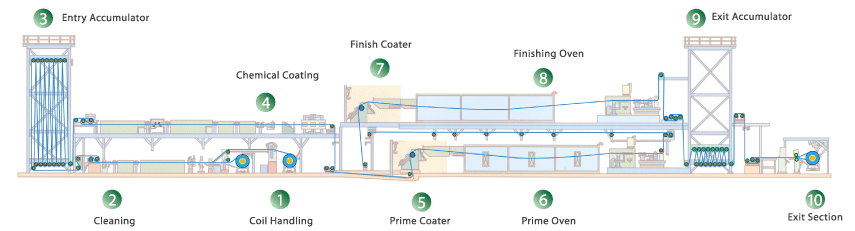

Color Coating Line (CCL)

The seven-stage pretreatment process yields a clean galvanized strip with a conversion coating, which is followed by a two-coat, two-bake process to provide aesthetically superior pre-painted galvanized steel with good metal-to-paint adhesion and uniform color, paint thickness, and surface finish. This product is suitable for various applications including in construction, domestic appliances, garden fencing, and garage doors.

The seven-stage pretreatment process yields a clean galvanized strip with a conversion coating, which is followed by a two-coat, two-bake process to provide aesthetically superior pre-painted galvanized steel with good metal-to-paint adhesion and uniform color, paint thickness, and surface finish. This product is suitable for various applications including in construction, domestic appliances, garden fencing, and garage doors.